METAL HEAD GASKET

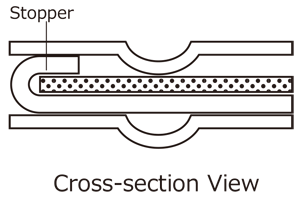

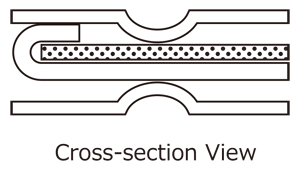

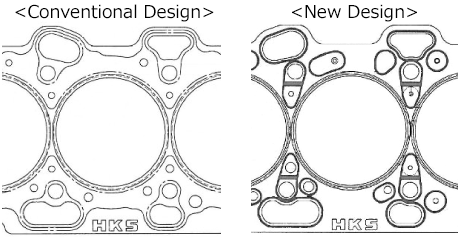

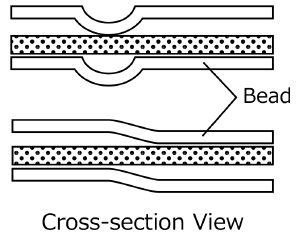

The Performance requirement from Head Gasket. As the cylinder block and head are not rigid body, when the Head Bolts are tightened, the gap between the surfaces and the surface pressure applied is not even across the whole surface. Moreover, due to combustion pressure and vibration while driving, the conditions are continually changing and the contact surface is being continually beaten. As a result, a good gasket must ensure that contact surface pressure is spread as evenly as possible and also adapt quickly to the ever changing gaps that can appear in the contact surface to maintain a good seal with good pressure.

More detailFilter By

Nallow down

- Product NameGROMMET TYPE HEAD GASKET G16E T=0.8MakeTOYOTAModelGR COROLLAYear2023-2025EngineG16E-GTSChassies#GZEA14HDriveAWDProduct#23002-AT003MSRP$290.00RemarksManualDetail

- Product NameGROMMET HGK SUPER COOLING Pro G16E t0.8MakeTOYOTAModelGR COROLLAYear2023-2025EngineG16E-GTSChassies#GZEA14HDriveAWDProduct#23002-AT007MSRP$300.00RemarksManualDetail

- Product NameGROMMET HGK SUPER COOLING Pro G16E t1.0MakeTOYOTAModelGR COROLLAYear2023-2025EngineG16E-GTSChassies#GZEA14HDriveAWDProduct#23002-AT008MSRP$380.00RemarksManualDetail

Open Application List

Details